Choose the right technology to optimize your cleaning process

Improve food safety, HACCP compliance, production time, operational costs and workplace safety by applying low-pressure technology with boosted water.

Cleaning and sanitizing in the food and beverage industry are one of the cornerstones of producing a product which is safe for the consumer to eat or drink.

Therefore, processors are and should be investing time and money to find the optimal cleaning solution that not only improves food safety and hygiene but is also efficient, sustainable, and user-friendly.

So, it is all about choosing a cleaning solution based on the right technology. While low-pressure technology with boosted water has been the prevailing cleaning technology in Europe in the past decades, it is still relatively unknown in the U.S. where high-pressure is the most used technology.

But why is it that LESS pressure is MORE effective than a higher pressure? Read on to get the answer.

LESS IS MORE

Studies show that low-pressure with boosted water is the superior technology for cleaning surfaces in the food and beverage industry compared to high-pressure. These are just some of the parameters:

- Higher rinse impact

- More effective removal of residues

- Lowest temperature drop

- Reduced risk of cross-contamination

- Improved working environment

The perfect combination of the correct temperature and volume of water in interaction with chemicals means that our solutions are optimised for cleaning the surfaces in all types of food and beverage processing facilities contaminated with fat, bacteria, yeast, microbes, limescales and other deposits. This way all surfaces are not only visually clean, but also bacteriologically clean.

Increased water flow

Tests clearly show that almost twice as much water reaches the object/surface with low-pressure cleaning compared to high-pressure (84% more).

More water on the object/surface significantly reduces cleaning time and speeds up the removal of residues. The effect of the increased flow reduces the total consumption of water.

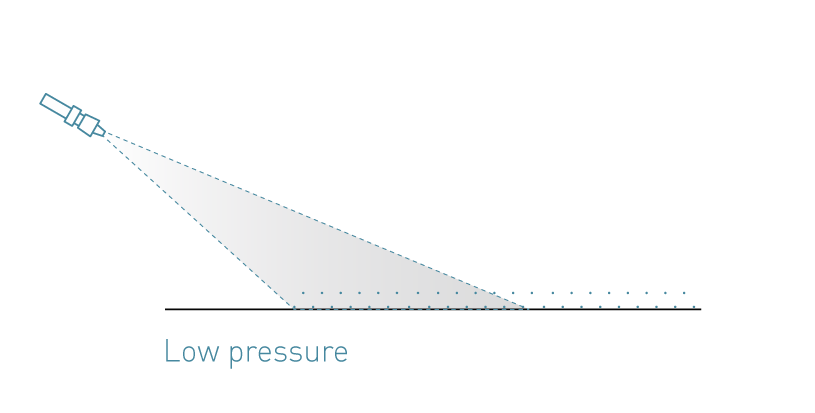

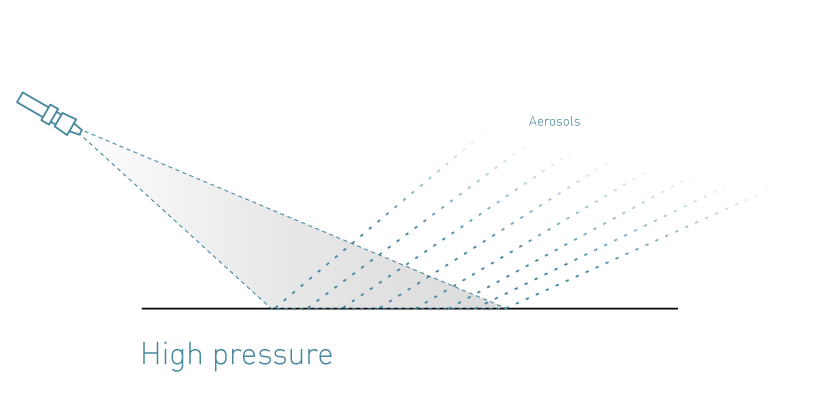

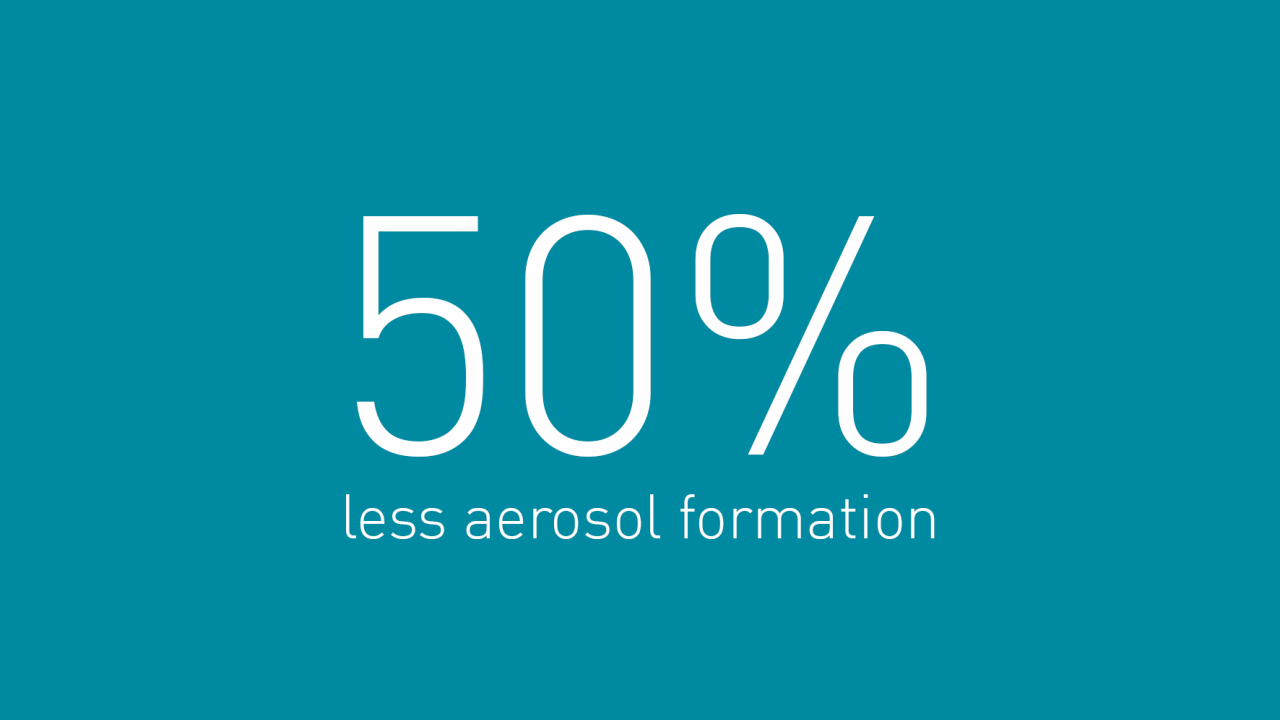

Reduction in aerosol formation

There has been focus on aerosols in connection with cleaning as this forms tiny droplets spreading in the air and easily inhaled, with the risk of causing respiratory problems. Aerosols can also transfer contaminated particles to already cleaned surfaces.

With low-pressure cleaning, the droplets formed are larger and reach the surface faster thereby reducing the risk of dispersion in the air. Tests show that the reduction is at least 50%.

Applying low-pressure technology with boosted water for cleaning in your processing facility significantly improves a range of key parameters

Good production hygiene and correct cleaning are essential when you want to produce quality products with a high level of food safety and optimal shelf life.

Optimizing on the cleaning process by using the right technology will not only have a positive impact on the quality of your products, but it will also improve the working environment for the cleaning staff as well as reduce cleaning time and water consumption.

Download our technology guide below and get a more detailed insight into the differences between low-pressure and high-pressure cleaning.

Download our technology guide below and get a more detailed insight into the differences between low-pressure and high-pressure cleaning.