Step inside the world of System Cleaners – the global leading manufacturer dedicated

to boosting hygiene around the world by means of strong open plant cleaning solutions and a promise

to never compromise and never complicate the journey.

A cleaning solution from System Cleaners offers a range of benefits

Reduced water and chemical consumption

Less wear on processing equipment and affected surfaces

Improved work environment

Low maintenance and service requirements

Significant reduction in cleaning time

SCCONNECT

Enabling Better Cleaning and Sustainable Consumption

The new monitoring system for manual cleaning

Automated cleaning

Integrating an automated cleaning solution ensures uniform cleaning of your food or beverage processing equipment, improves levels of food safety and hygiene, and reduces cleaning time and operational costs.

Manual cleaning

Our manual equipment range is extensive and offers the possibility to customize the solution to meet your needs and challenges. Our technology ensures effective cleaning with higher impact and less aerosol formation.

Mobile cleaning

A mobile solution allows you to cover a large area without having to invest in multiple systems. We offer satellites on trolleys as well as stand-alone mobile main stations with more features for even more flexibility.

Designing customized cleaning solutions for a wide range of applications is one of our core competencies

Our skilled engineers and solutions architects have extensive expertise in mapping out the cleaning process and designing a system that matches the individual application 100%. You can access three of our most sought-after solutions below, or click here to go to the application overview.

External filler cleaning - EFC

Integrating automated EFC on your filler ensures a consistent and high-quality cleaning result every time. Moreover, it reduces the cleaning time significantly thereby increasing production time and volume.

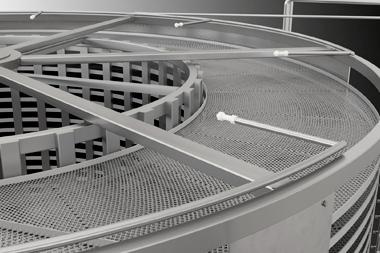

Spiral freezer cleaning

Implementing automated cleaning on your spiral freezer lets you benefit from significantly reduced cleaning times (up to 57%) and labour costs (up to 83%) as well as a more consistent and effective cleaning result.

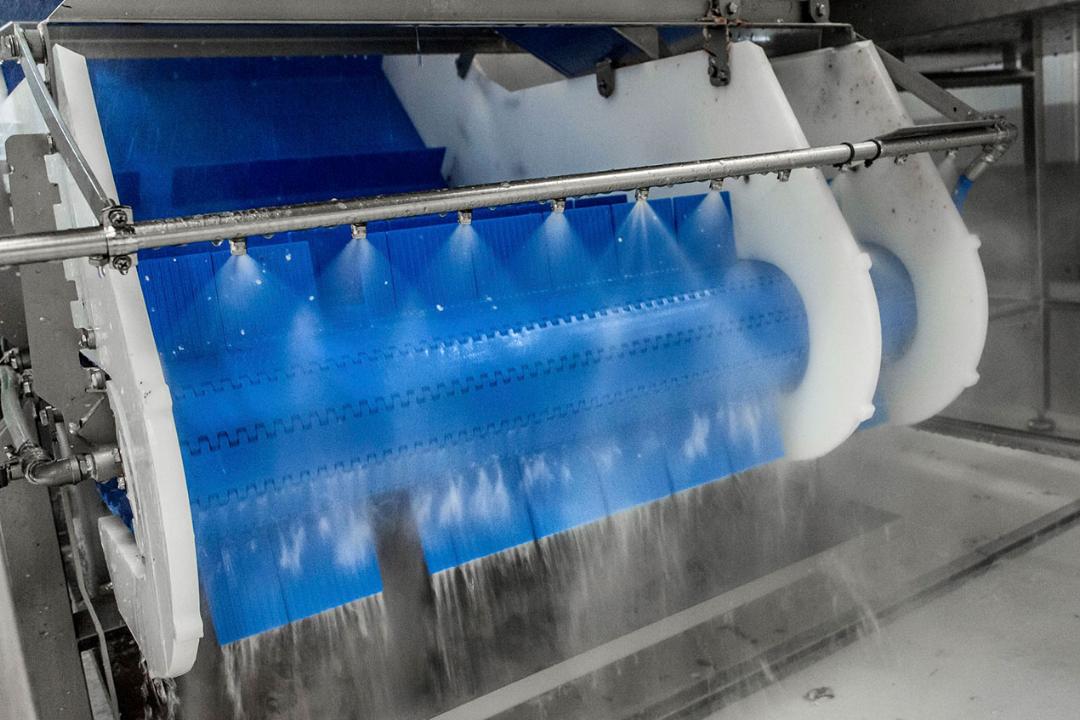

Conveyor belt cleaning

Nozzle bars are placed in strategic places internally and externally on the conveyor to ensure that every inch of the belt is cleaned and sanitized to prevent microbial growth.

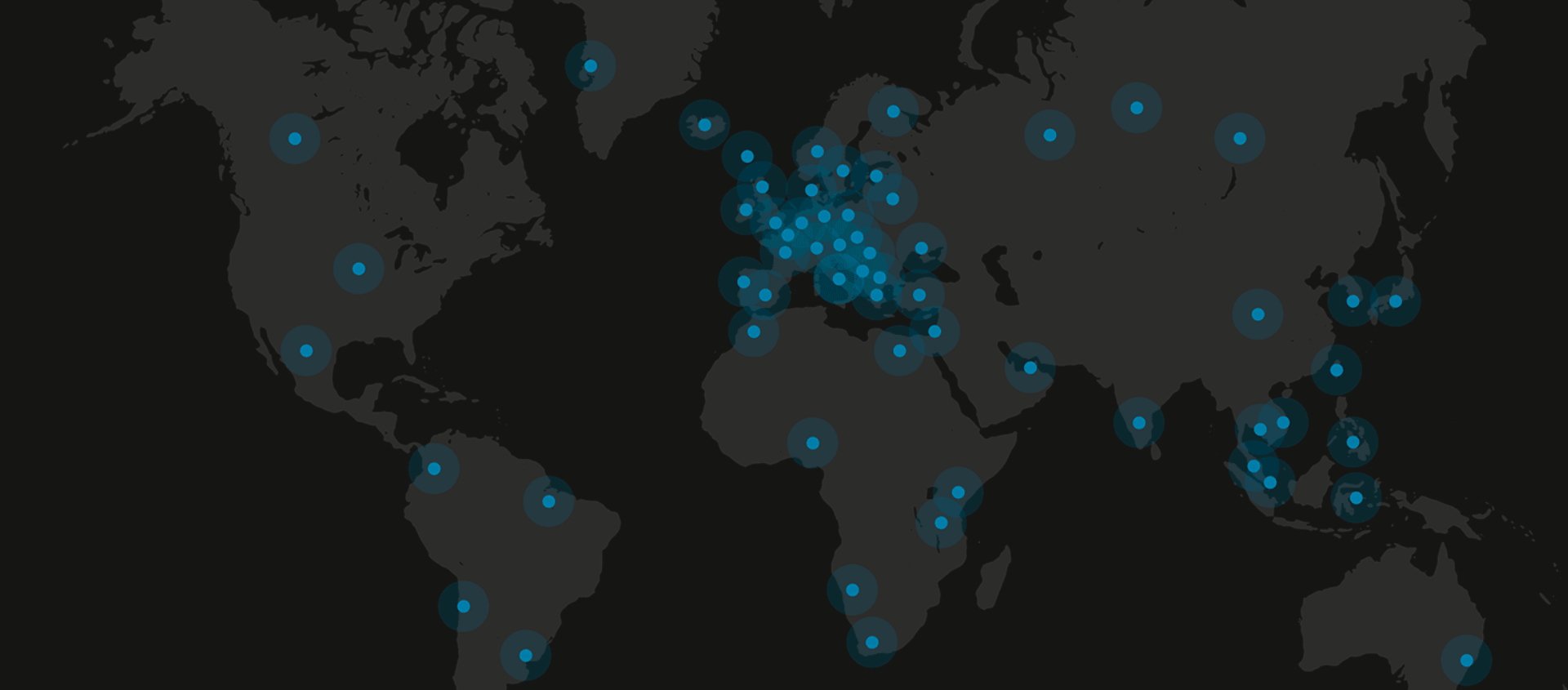

We're part of something bigger

We are always close to you

represented in 100+ countries through our extensive partner network

We have supplied more than 150,000 cleaning units worldwide

Succesful food and beverage companies all over the world have increased the level of hygiene and food safety with our open plant cleaning solutions

Pineland Farms Natural Meats

“The use of low-pressure technology with boosted water has proved to be a very good idea. We’ve experienced reduced cleaning times as well as lowered our water consumption."

Chris Williams, Sr Vice President

Polar Seafood

The Rolls Royce super-trawler Markus is a highly automated, floating processing plant featuring a System Cleaners cleaning solution safeguarding the massive catch of 9000 tonnes of shrimp and 3000 tonnes of mackerel against contamination.

Naturmælk

The organic dairy Naturmælk supplies a wide range of organic products to one of the largest supermarket chains in Denmark. They apply a System Cleaners open plant cleaning solution to clean their production.