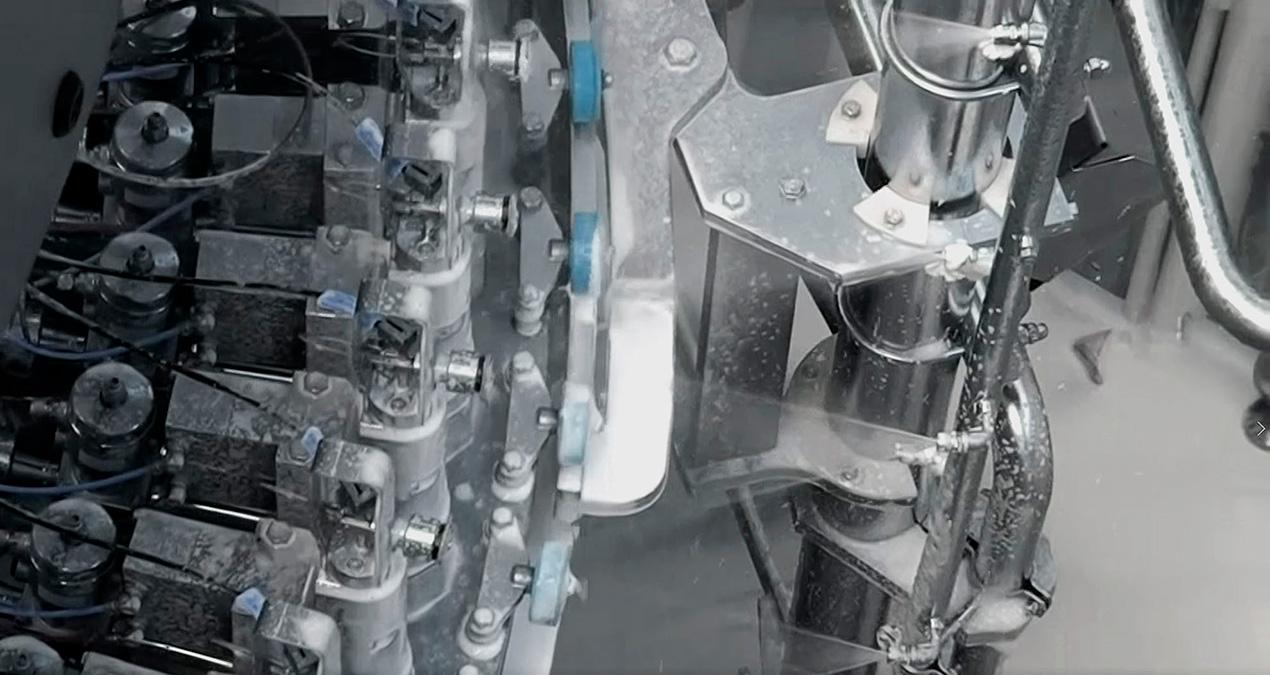

Automated external filler cleaning - EFC

Cleaning a filler poses a range of challenges, e.g., the temperature and consistency of the product, the capacity and speed of the filler, the number of flavours, or product changes. Every filler has its own characteristics and requirements, and consequently the cleaning solution must be adapted to meet these requirements.

Discrepancies between cleaning procedures and filler will result in inadequate levels of food safety and hygiene.

Build-up of bacteria, mould, yeast etc. in critical zones on the filler, for example bowl, valves, and snifters, will eventually result in contamination of the product, and ultimately have a negative impact on your bottom line and your brand value.

Integrating automated EFC on your filler ensures a consistent and high-quality cleaning result every time. Moreover, it reduces the cleaning time significantly thereby increasing production time and volume.

Standard and high-flow EFC solutions

When applying automatic external filler cleaning, the cleaning process is divided into segments. The number of segments depends on the nature of the filler and whether the shielding is incorporated in the process.

The average number of segments is approximately 12, six dedicated for filler and six segments for the shielding. With standard EFC, the segments are activated one at a time. With high-flow EFC, up to 6 segments can be activated at the same time, making it possible to reduce cleaning time by up to 45%.

The significantly reduced cleaning time facilitates higher throughput, enabling a return on investment down to 6 months.

.jpg&)

Ensuring a consistent and high-quality cleaning result every time by integrating automatic EFC system means:

- Significant reduction in cleaning time, extending production time and facilitating higher through-put

- Improvement in hygiene and food safety levels

- Consistency in product quality – no contamination

- Significant reduction in water consumption

- Reduced labour costs – fewer employees

- Higher safety levels

- High return on investment - down to 6 months

Low-pressure cleaning with boosted water offers a range of benefits

Significant reduction in cleaning time

Reduced water and chemical consumption

Less wear on processing equipment and affected surfaces

Improved work environment

Low maintenance and service requirements

Our products

Our automated EFC systems consist of standard elements comprised into customized systems matching your filler and the requirements you have for optimizing the cleaning and sanitation processes in your beverage processing plant.

The design is hygienic and intuitive, and they are made from high quality materials. By applying stainless steel for the vast majority of the components, we ensure that our products are solid and with a long lifespan.

We're here to help

We have extensive expertise in creating customised cleaning solutions for fillers. By mapping out the cleaning process based on the filler's construction, we can determine the optimal segmentation of the process.

If you’re interested in more information about how we can help you maintain a high level of hygiene and food safety in your beverage processing plant, don’t hesitate to contact our Sales team for an informal chat.

We are ready to listen.