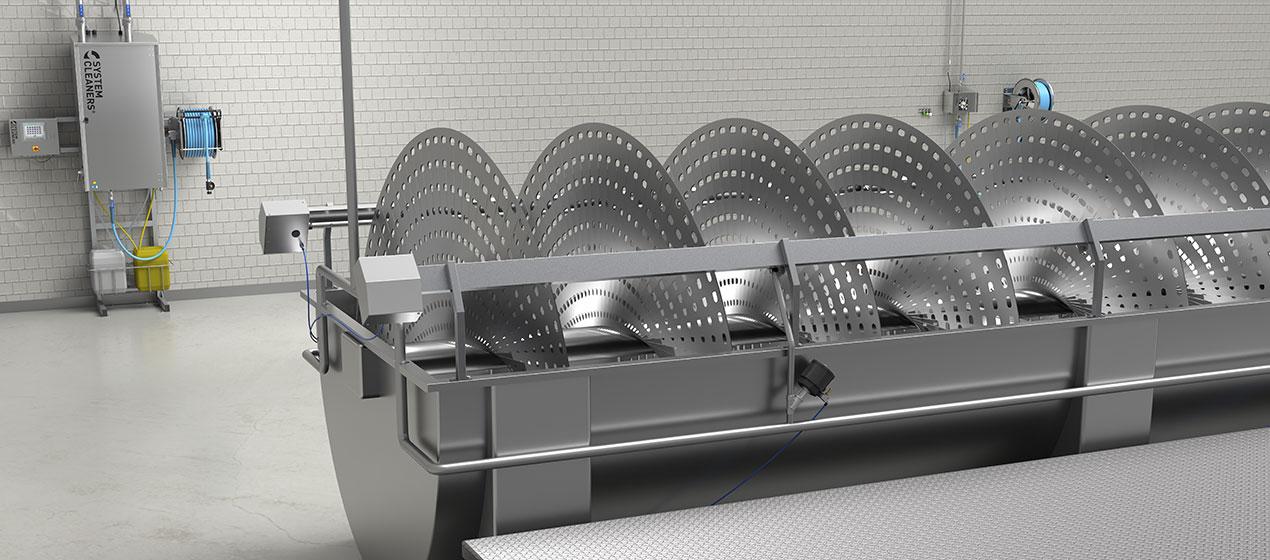

Automated cleaning of spin chiller

Spin chiller, screw chiller, water chilling tank, screw tank – it goes by many names. But the fact is that the spin chiller is a key piece of processing equipment in the poultry processing industry. It is the first step where food safety issues can be prevented, and it is the process that initially determines the product quality and shelf-life. The chilling process decreases bacterial growth as the carcasses are moved at a constant pace through the chiller in a specific amount of time to ensure the correct end temperature before they continue down the processing line.

The immersion of a vast amount of carcasses into the same pool of water consitutes a risk of cross-contamination within the batch and between batches, even with the use of antimicrobials.

Residues will build up in the chiller, especially by the edge of the water where waste from the carcasses floats. These residues may contain pathogens such as Salmonella that need to be removed in order not to contaminate the next batch.

Having the right cleaning solution for your spin chiller is essential in preventing cross-contamination. Manual cleaning is time-consuming and the result is often dissatisfactory.

An automated solution offers consistent and effective cleaning, improved levels of food safety and hygiene, and reduced cleaning times. Moreover, labor requirements are reduced and safety levels are increased.

Key benefits of automated cleaning

Manual cleaning is time-consuming and often inconsistent as the chiller is moving during cleaning. To ensure the optimum production flow while maintaining a high level of hygiene and food safety, it is essential to implement an effective and consistent cleaning process.

Integrating automated cleaning on your spin chiller ensures a consistent and high-quality cleaning result every time. It reduces the cleaning time enabling more production time, and labour costs are significantly reduced.

Getting a consistent and high-quality cleaning result every time by integrating automated cleaning means:

- Significant reduction in cleaning time, extending production time and facilitating higher through-put

- Improvement in hygiene and food safety levels

- Consistency in product quality – no contamination

- Significant reduction in water consumption

- Reduced labour costs – fewer employees

- Higher safety levels

Low-pressure cleaning with boosted water offers a range of benefits

Significant reduction in cleaning time

Reduced water and chemical consumption

Less wear on processing equipment and affected surfaces

Improved work environment

Low maintenance and service requirements

Our products

Our automated solution for spin chiller cleaning and sanitation can be customized to match any chiller. Standard components are combined into a unique solution to match the specific requirements, and the solution can be applied to all types of spin chillers.

The design is hygienic and intuitive, and they are made from high quality materials. By applying stainless steel for the vast majority of the components, we ensure that our products are solid and with a long lifespan.

We're here to help

Investing in an automated cleaning solution has a significant and positive impact on a wide range of parameters. We have developed a framework in which we can enter your details and, based on these, see what you can gain in terms of production time, capacity and profit.

If you’re interested in more information about how we can help you maintain a high level of hygiene and food safety in your processing plant, don’t hesitate to contact our Sales team for an informal chat.

We are ready to listen.