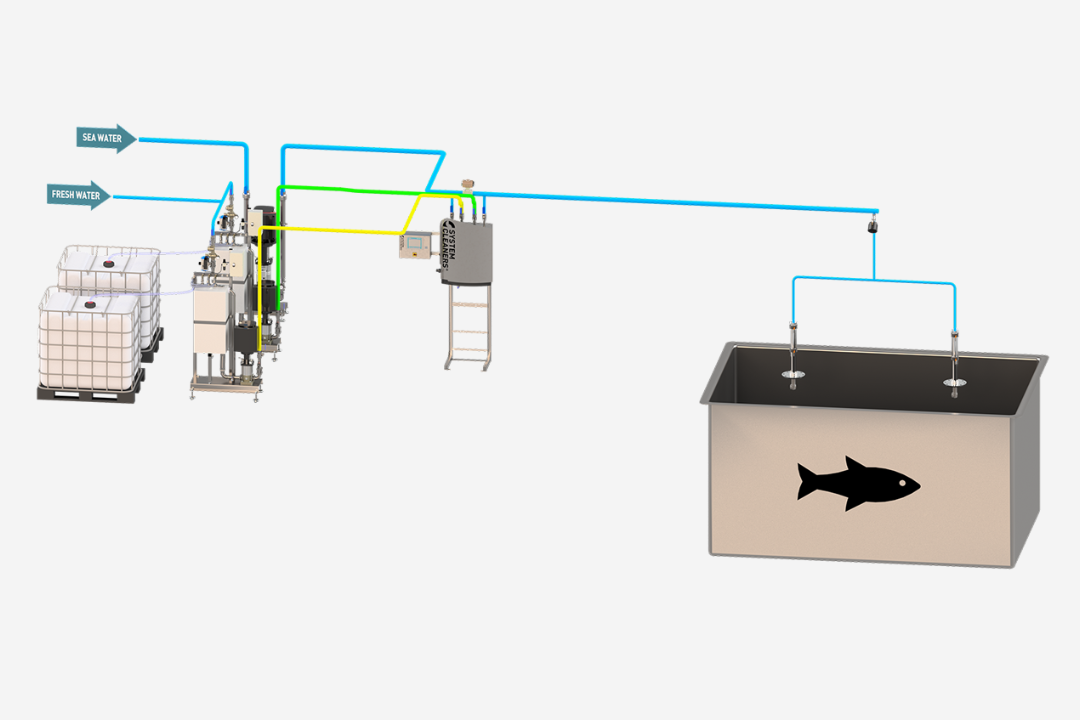

Automated tank cleaning

The use of tanks, vessels and totes in the food and beverage industry is extensive and has numerous applications. A wide variety of food and beverages is processed and stored in them and consequently, the nature of the leftover soil is equally varied. This fact requires different solutions for different applications to ensure they are adequately cleaned.

Manual cleaning of tanks is prone to inconsistencies, poses safety hazards for staff and require vast amount of water. It may not even be possible to clean them manually due to confined space. And with very large sanitary tanks, manual cleaning is not cost-effective. An automated cleaning system optimise on all parameters.

Different solutions for different applications

Depending on the nature and the resilience of the soil and your requirements, we offer different cleaning systems:

- Tank cleaning with fixed nozzle bars

- Tank cleaning with fluid-driven, rotating nozzle

- Tank cleaning with gear-driven, rotating nozzle for wider reach and impact

Our cleaning systems are based on low-pressure cleaning technology with boosted water no matter what solution you choose. This technology ensures higher impact of water jet, lowest temperature drop and more effective removal of soil. 84% more water reaches the surface compared to a high-pressure solution, and the increased water flow enables better cleaning in less time.

The benefits of automated cleaning

With an automated cleaning system on any piece of processing equipment, you get a consistent cleaning result of high quality. The system is not just a plug-and-play installation – it is carefully tailored to match the construction of the processing equipment and to consider the inaccessible areas that require extra attention.

The cleaning process is operated by a controller in which each segment is adapted to the cleaning demands of the equipment. There are several benefits to this system:

- Reduced cleaning time

- Improved levels of food safety and hygiene

- No cross-contamination

- Consistent product quality

- Employee safety

- Reduced water and chemical consumption

Way up high

Up north in the Atlantic you find the capelin fish. The capelin roe, also called masago, is considered a high-value product in Japan as ingredient in a wide variety of dishes. A few weeks every year, the roe from the female fish is harvested and stored in large tanks awaiting export.

When the tank is empty, two automated cleaning systems are activated. A gear-driven, rotating nozzle is effectively rinsing the entire tank. Fixed nozzle bars are then administering the chemical products ensuring that foam and disinfection cover the entire tank wall. This way all pathogens are removed and food safety as well as consistency in product quality is secured.

Case: Ronja Ocean

"Now we don’t have to enter the delousing tank dressed in boiler suit and water proofs, and the cleaning time has been significantly reduced. The working day is simpler, we have time for other tasks and the delousing unit is ready for the next batch of fish faster than before,” the seamen on Ronja Ocean Tellef T. Elverum and André Balstad state."

Low-pressure cleaning with boosted water offers a range of benefits

Significant reduction in cleaning time

Reduced water and chemical consumption

Less wear on processing equipment and affected surfaces

Improved work environment

Low maintenance and service requirements

We're here to help

We can help you maintain a high level of hygiene and food safety in your food or beverage processing plant. If you’re interested in more information about an automated system for tank cleaning, don’t hesitate to contact our Sales team for an informal chat.

We are ready to listen.