Automated cleaning of eviscerator

Large-scale poultry processing plants are equipped with a wide range of processing equipment, each handling specific steps on the production line. Many of these steps have become automated over the past decades ensuring a high yield that accommodates the increasing demand for poultry products.

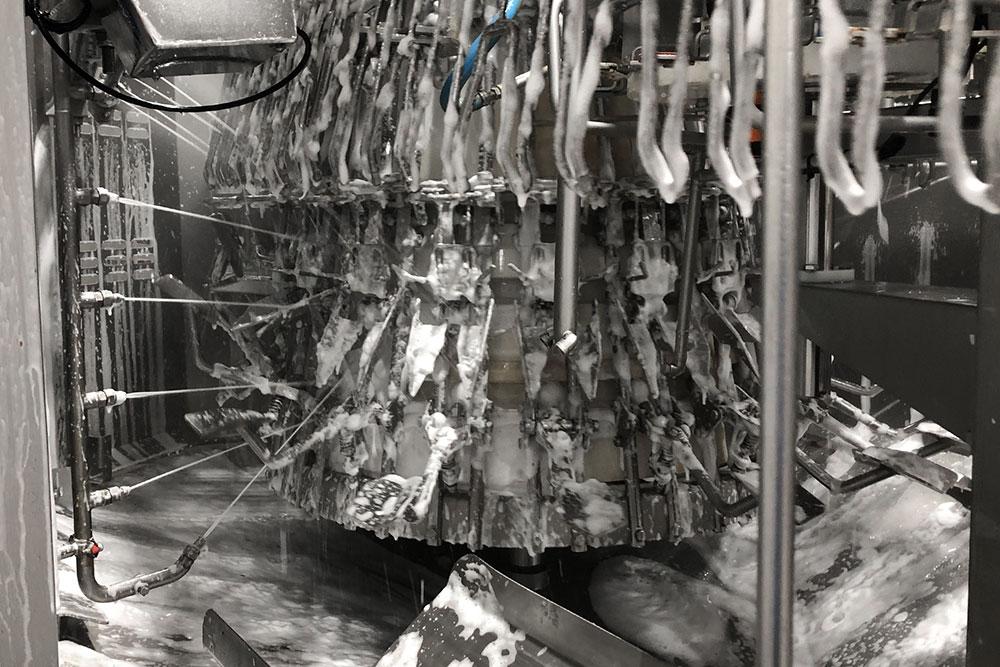

One step in the primary processing that requires precision and care is the evisceration. The evisceration process consists of several steps where the internal organs are removed from the carcass. The eviscerator is typically constructed as a carousel able to eviscerate up to 13,500 birds per hour. A blade cuts open the cavity, and an arm draws out the viscera pack and hangs it for veterinary inspection.

This process poses the risk of the guts spilling out and contaminating the meat of the carcasses by exposing it to high microbial loads.

Like any other piece of processing equipment in the food and beverage industry, thorough cleaning in between batches is essential to ensure a high level of hygiene and prevent cross-contamination. The eviscerator is a complex construction with many hard-to-reach areas and applying only manual cleaning increases the risk of cross-contamination.

Irregularities in the final cleaning result may be caused by scarcity in qualified labour, limited access to certain parts of the eviscerator and the fact that it is in constant motion.

Food safety and workers’ safety

Integrating automated cleaning on the eviscerator reduces the risk of cross-contamination thereby increasing the level of food safety. Nozzles are placed in areas where manual cleaning cannot reach properly, making the cleaning much more effective and consistent. The complexity of the eviscerator, however, allows for organic material getting stuck in every notch and groove on the equipment, and therefore still requires a certain degree of manual removal of gross soil prior to the automated cleaning.

Automation of the cleaning also reduces the risks associated with the cleaning of moving equipment. Even though the speed of the line is heavily reduced compared to production speed, there is still the risk of physical contact with the equipment, especially when trying to reach behind the line to the not so readily accessible areas. Reducing manual cleaning also reduces this risk.

Benefits of automated cleaning of eviscerator:

- Improved levels of hygiene and food safety

- Reduces the cleaning time – extending production time

- Reaches the ‘dark spots’ on the eviscerator

- Improves workplace safety

- Reduces labour costs

- Prevents contamination and microbial growth

Low-pressure cleaning with boosted water offers a range of benefits

Significant reduction in cleaning time

Reduced water and chemical consumption

Less wear on processing equipment and affected surfaces

Improved work environment

Low maintenance and service requirements

Case: Processing 1,000,000 chickens per day

One of the world’s leading poultry processors was in the market for an open plant cleaning solution to optimize production efficiency and hygiene in the company’s primary processing facilities.

20 hours of processing and a flow of 1,000,000 chickens each day creates a very busy workday demanding an efficient open plant cleaning (OPC) solution to facilitate smooth operations and keep the processing equipment and other surfaces clean.

With an automated cleaning solution, they have optimized on cleaning time as well as hygiene.

An automated cleaning system for your eviscerator is not a plug-and-play solution. It takes a high degree of customization to make sure that all areas on the equipment are effectively cleaned and sanitized. Our solutions are constructed from standard components combined into a unique system matching the eviscerator in question.

Our products

A System Cleaners automated cleaning solution for eviscerators consists of standard products combined to match the requirements you have for optimizing the cleaning and sanitation processes in your food or beverage processing plant.

The design is hygienic and intuitive, and the system is made from high-quality materials. By applying stainless steel for the vast majority of the components, we ensure that our products are solid, have a long lifespan and as recyclable as possible.

We're here to help

We can help you maintain a high level of hygiene and food safety in your food or beverage processing plant. If you’re interested in more information about an automated system for eviscerator cleaning, don’t hesitate to contact our Sales team for an informal chat.

We are ready to listen.