Floor washing solutions

The floor in the food or beverage processing plant is often a secondary consideration, but it is a vital component in the cleaning procedures as it harbours harmful bacteria and viruses that can contaminate food products. Cleaning and sanitising them is therefore very important.

The first step to a clean floor is having a floor that is constructed to meet the demands of a food or beverage processing facility. It needs to be hygienic, waterproof, and easy to clean to prevent bacterial growth in cracks and rough spots.

For cleaning, mops and brooms are not recommended. When mopping the floor, the water in the bucket and the mop will quickly become contaminated and spread bacteria when applied. Using a broom can stir up dirt on the floor and aerosolize contaminated water carrying microorganisms.

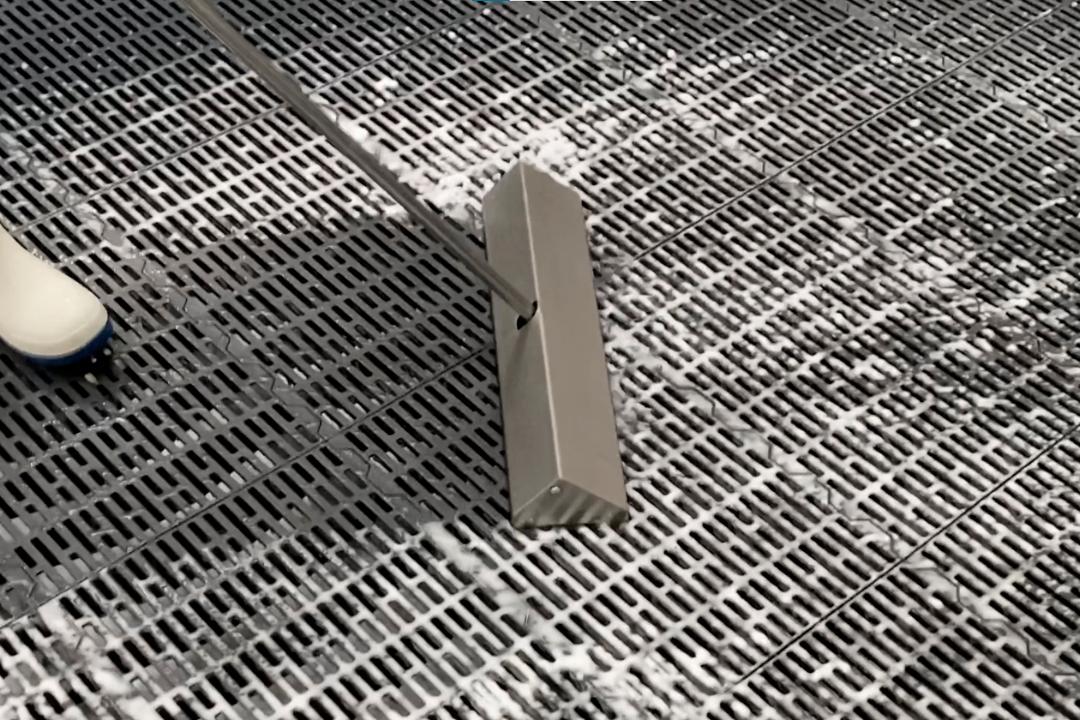

Floor washer & rotating brushes

For larger facilities and areas, the most common way of cleaning the floor is with an industrial scrubber. But for areas not easily accessed with a big, industrial machine it is necessary to find an alternative solution.

To that end, we have developed two different solutions:

- A floor washer designed with a nozzle bar and stainless-steel shielding (3 different widths)

- A rotating single-brush or triple-brush scrubber

Both for connection to a boosted water supply from a System Cleaners supply station.

Specifications:

Floor washers:

- Width options: 400 mm, 600 mm and 800 mm (5,7 and 8 nozzles)

- Water consumption: 40-64 liter/min at 20 bar

- Connection: 1/2" SC coupling nipple

- Material: Stainless steel AISI 304, nylon (nozzles: AISI 303)

Rotating brushes:

- Options: 1 or 3 brushes

- Pipe length: standard, 1.5 m and 2.5 m

- Brush diameter: 200 mm

- Connection: 1/2" SC coupling nipple

- Material: Stainless steel AISI 304, nylon

Low-pressure cleaning with boosted water offers a range of benefits

Significant reduction in cleaning time

Reduced water and chemical consumption

Less wear on processing equipment and affected surfaces

Improved work environment

Low maintenance and service requirements

Get in touch with us

If you are interested in getting more information about our open plant cleaning solutions or have any questions or queries, please fill out the quick form and we will get back to you as soon as we can.