Automated cleaning of deboning machine

As the eating habits of consumers are shifting towards more convenience, both when cooking at home and in terms of ready-to-eat meals, the market for deboned poultry products is growing. Consequently, poultry processors are faced with the need for increased yield as well as maximising production time to meet the demands of consumers.

At the same time, the necessity to shut down production to keep a high level of hygiene and food safety can be a limiting factor.

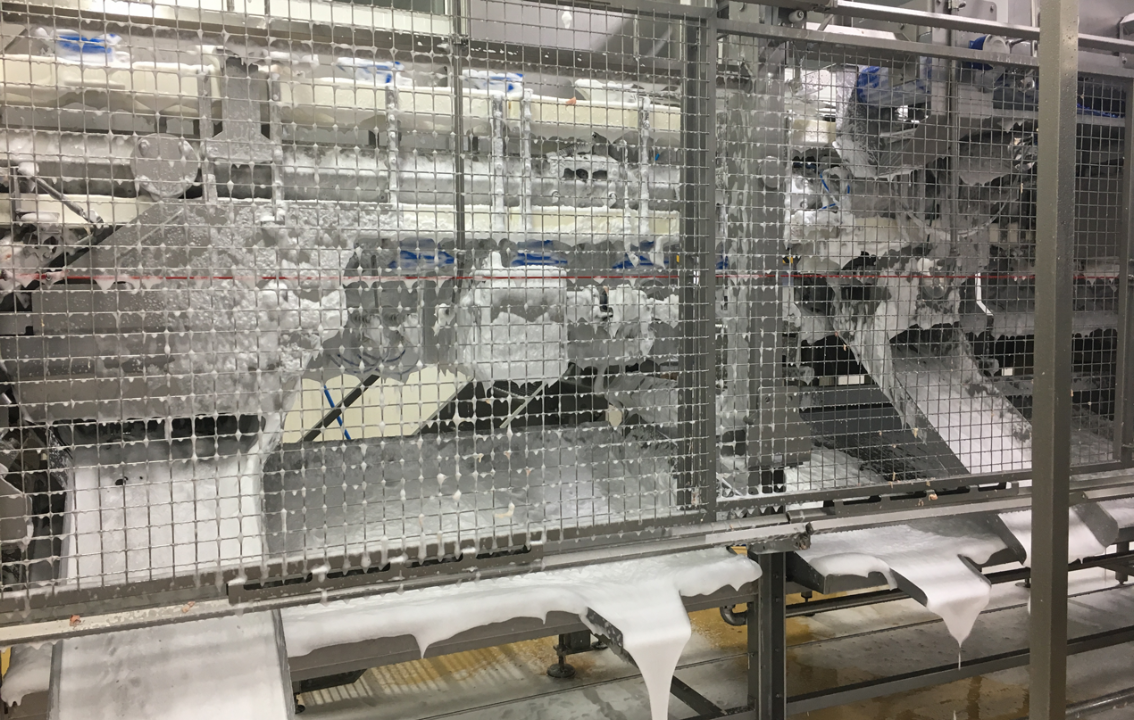

Cleaning and sanitising a deboning machine manually take a lot of manpower and a lot of time. There is a lot of shielded spots, recesses, and areas hard to reach on the machine, and this construction makes strictly manual cleaning difficult. And for the cleaning staff, it can be a hazardous affair as the deboning machine is moving during cleaning.

With an automated solution, it is possible to get past these issues.

Key benefits of automated cleaning

Nozzle bars are placed on the equipment to cover all surfaces, and the cleaning process is segmented to ensure that all areas are cleaned properly. If a section requires extra attention, the cleaning program will be adjusted to match this.

But no matter what type of deboning machine you have, manual knock-down of gross soil will always be necessary to some extent. However, the requirement for manual labour, and thus the inherent costs, are considerable reduced and consequently also workplace safety.

Enabling a consistent and high-quality cleaning result every time by integrating automated cleaning presents numerous benefits:

- Significant reduction in cleaning time, thereby extending production time and facilitating a higher yield

- Improvement in the level of hygiene and food safety

- Consistent product quality – no cross-contamination

- Reduction in water consumption

- Reduction in labour costs and requirements

- Reduction in workplace hazards

Low-pressure cleaning with boosted water offers a range of benefits

Significant reduction in cleaning time

Reduced water and chemical consumption

Less wear on processing equipment and affected surfaces

Improved work environment

Low maintenance and service requirements

Our products

Our automated solution for cleaning and sanitising of deboning machines can be customized to match any type of deboner. Standard components are combined into a unique solution to match the specific requirements.

The design is hygienic and intuitive, and they are made from high quality materials. By applying stainless steel for the vast majority of the components, we ensure that our products are solid and with a long lifespan.

We're here to help

Investing in an automated cleaning solution has a significant and positive impact on a wide range of parameters.

If you’re interested in more information about how we can help you maintain a high level of hygiene and food safety in your processing plant, don’t hesitate to contact our Sales team for an informal chat.

We are ready to listen.