Beating bacteria and fat in Brazil

The challenge

One of the world’s largest food processors, operating numerous production sites and distribution centres across the globe, supplies food products to more than a hundred countries worldwide.

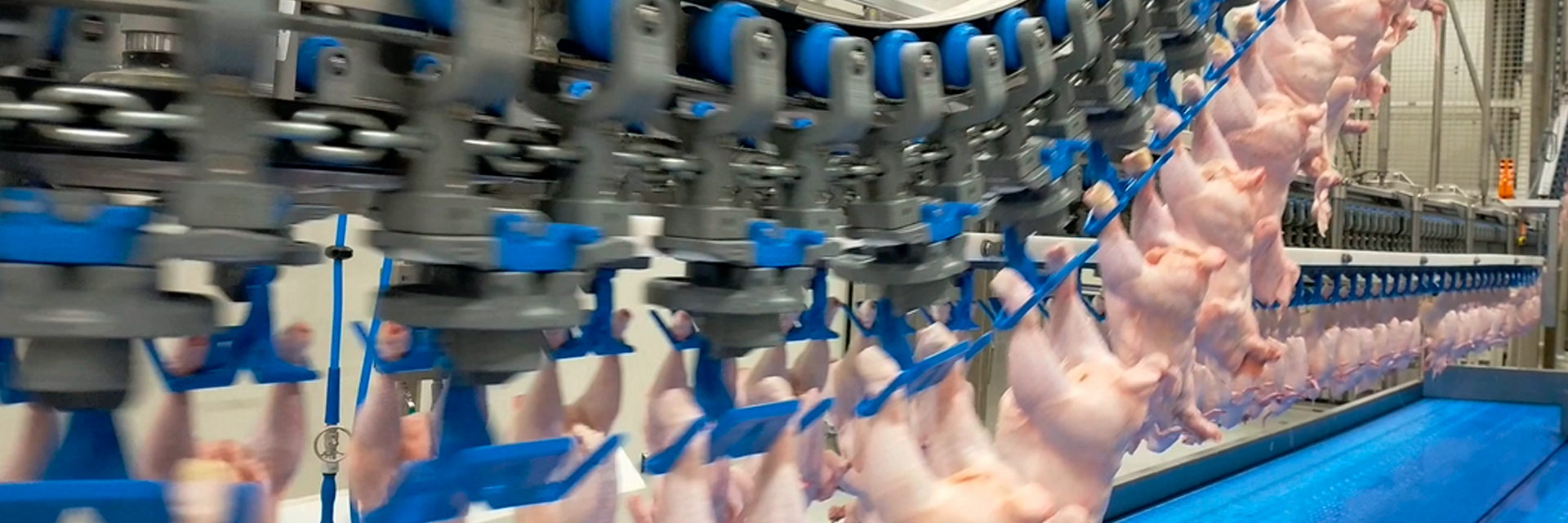

At one of their processing sites, around 500,000 chickens are processed daily. Production challenges must be optimised to keep the site running at full capacity.

In this case, the challenge was the cleaning of the spin chiller.

The spin chiller is the first step in the processing line where food safety issues can be prevented. It also initially determines the quality and shelf life of the final product. The chilling process reduces bacterial growth as the carcasses are moved through the chiller to ensure the correct temperature is maintained before continuing down the processing line.

So, it’s an essential piece of equipment for securing food safety in poultry products.

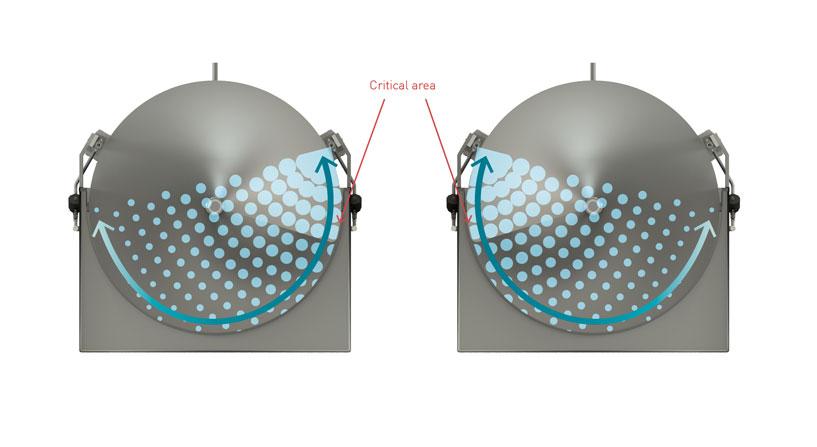

Please note that this is not an exact illustration of the installation

Please note that this is not an exact illustration of the installation

Resilient residues

Manual cleaning of the 22-metre-long spin chiller was time-consuming and challenging, as fatty residues from the chilling process adhered to its surface. Therefore, finding an alternative solution to remove the resilient fat was vital.

They wanted to set up a pilot project to test and, if successful, implement automated cleaning on equipment at more processing sites, and they decided on a System Cleaners solution.

Our solution team designed a customized system based on the construction of the spin chiller and calculations of the optimal segment size and flow rate.

Excellent cleaning results

Switching from manual to automated cleaning of the spin chiller proved to be a wise decision.

After integrating the system on the chiller, the optimisation process began: subtle adjustments to spray angles and the addition of nozzles ensured complete coverage of the chiller tank, shaft, and screw flights.

Subsequently, the processor’s QA-team performed tests and found only two small spots of fat on the 22-metre-long piece of equipment.

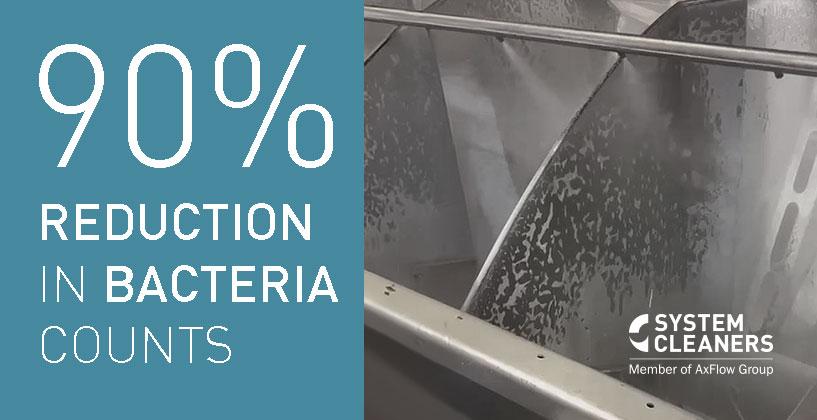

The bacterial tests revealed a 90% reduction in positives.

Moreover, labour requirements were reduced by 50%, adding a bonus to the integration.

The solution setup

The entire cleaning solution is comprised of:

- AM200 automatic main station

- Oscillating nozzle bars with drives

- Controller

- Segment valves

The integrated Grundfos pump in the automatic main station pressurises water and chemicals, then supplies them to the nozzle system.

Oscillating nozzle bars are placed on angled rails on both sides of the spin chiller, ensuring maximum water jet impact. The areas where the water’s surface deposits residues are critical, as these may harbour bacteria, and the nozzles are placed to provide the most significant impact here.

Read more about the benefits that you can gain by integrating automated cleaning in this link.