European brewery

A customer in the brewery industry approached us with the hope of solving their capacity problems without compromising on hygiene and without using more water and chemicals.

They were already using standard automated cleaning on their two fillers, so the solution had to be extraordinary.

The basic problem was that the demand for their products exceeded the capacity of their fillers. Even with standard automated cleaning, the time span for cleaning was limited, particularly during peak season. Investing in a third filler was not an option.

So, the only parameter to adjust was the cleaning time.

The solution

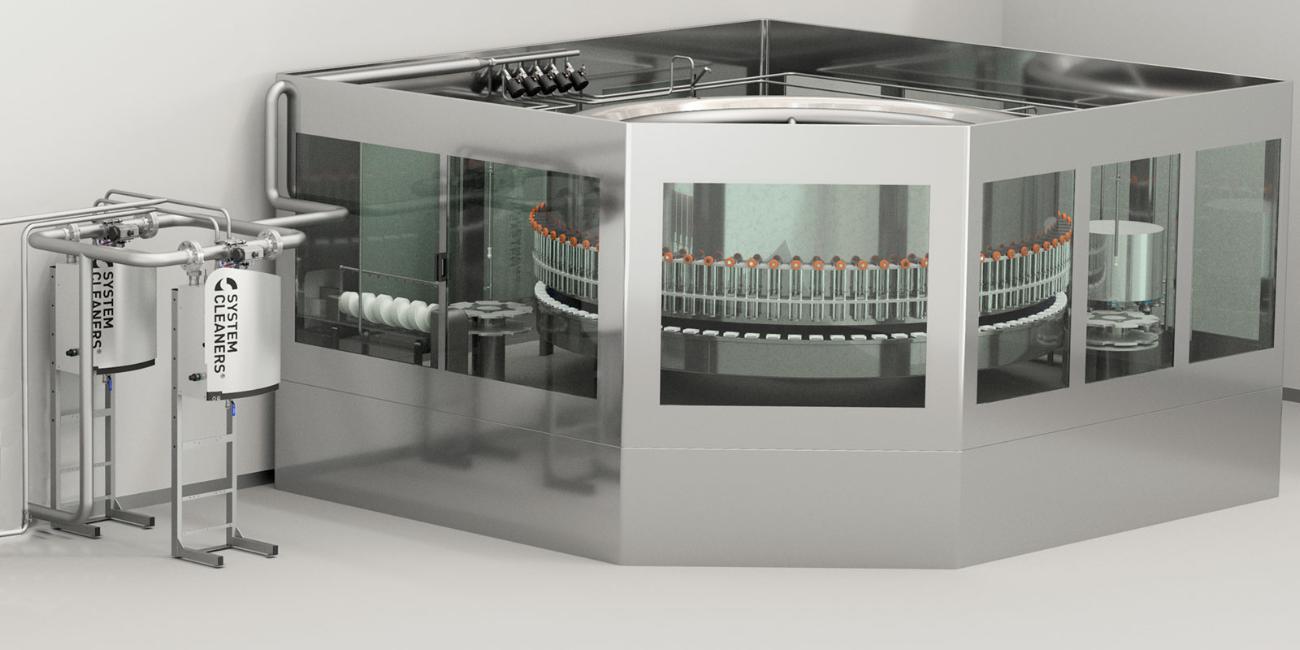

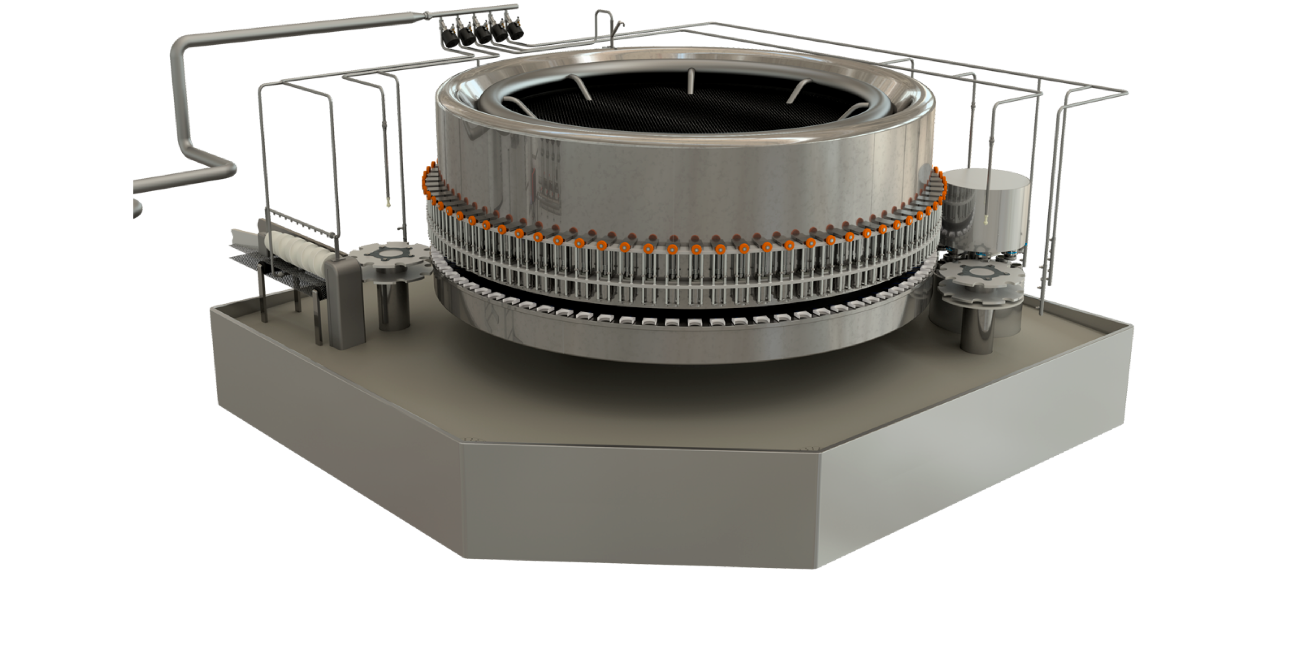

To enable a faster cleaning process, the water supply, pump capacity and chemical capacity had to be increased. We swapped the existing satellite with two customized high-flow automatic satellites for each filler and upgraded the booster pumps and chemical pump stations. The piping was adapted to the increased water flow.

With the standard automated cleaning, the cleaning process was segmented into zones. The segments were activated one at a time to ensure sufficient water supply for the nozzle systems.

By allowing for an increased water flow, it is now possible to activate all segments at the same time, resulting in a reduced cleaning time of 45% WITHOUT compromising on hygiene and WITHOUT using more water and chemicals.

The brewery went from cleaning each filler three times a day for 32 minutes per cleaning cycle to 18 minutes per cycle, saving 42 minutes every day on each filler!

Calculating the return on investment

The reduced cleaning time means that the brewery can produce 2x42 minutes extra each day. Based on the throughput of one filler, the following calculation can be set up:

Production time: 20 hours/day - 30 days/month

Output: 72,000 cans/hour

Additional output: 42 min/day = 50,400 cans/day

Factoring in the financial investment and the profit from each can of beer, the open plant cleaning system will have a return on investment in just 6 months.

Visit the EFC landing page to learn more