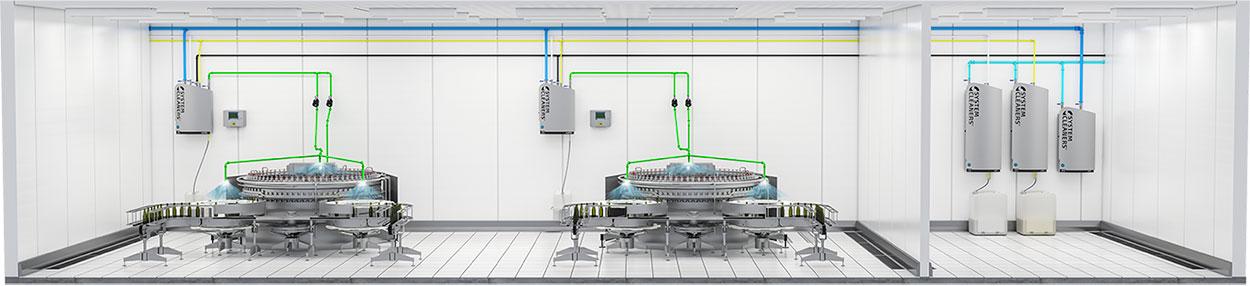

Chemical supply: Central, decentral or hybrid?

When you choose an open plant cleaning system for your processing facility, it is essential to consider what the setup of the chemical supply should be. Each processing plant has its own characteristics, and the requirements for a cleaning system depend on various factors:

- Is it a new or existing processing plant?

- Is there a corporate chemical handling policy dictating that chemicals are prohibited in the production area?

The chemical supply system can be either central, decentral or hybrid. There are advantages and disadvantages to all setups.

A centralised system initially requires a larger investment due to the extensive pipework needed, but subsequent savings on other procedures enables an attractive return on investment. A decentral system is less expensive but provides less consistency in terms of dosing.

The setup of the system is the same in both automated and manual cleaning solutions.

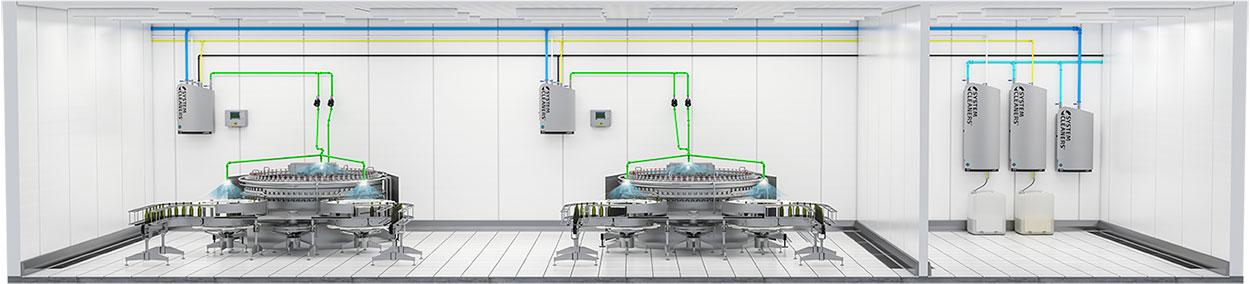

Central chemical supply

A central solution is characterized by prediluted chemicals being pumped to each workstation from a chemical pump station placed in a separate, central location.

It minimizes the daily handling of chemicals, ensures uniform concentration for all users/workstations and makes operating the system as simple and safe as possible.

The solution is often recommended in connection with the expansion of production facilities and/or the construction of new.

If the company has a chemical handling policy that prohibits chemicals in the production area, a central setup is the optimal solution.

Advantages:

- Efficient and constant chemical consumption: dosing and titration is performed at the central chemical pump station and ensures consistent concentration at all workstations.

- Safety: the minimization of the daily handling of chemicals improves health and safety for staff.

- The lack of chemical handling also makes the work more efficient as chemical cans will not have to be moved around.

- Cost-effective purchase of chemicals as they can be purchased in larger quantities. It minimizes chemical waste and reduces the use of plastic cans.

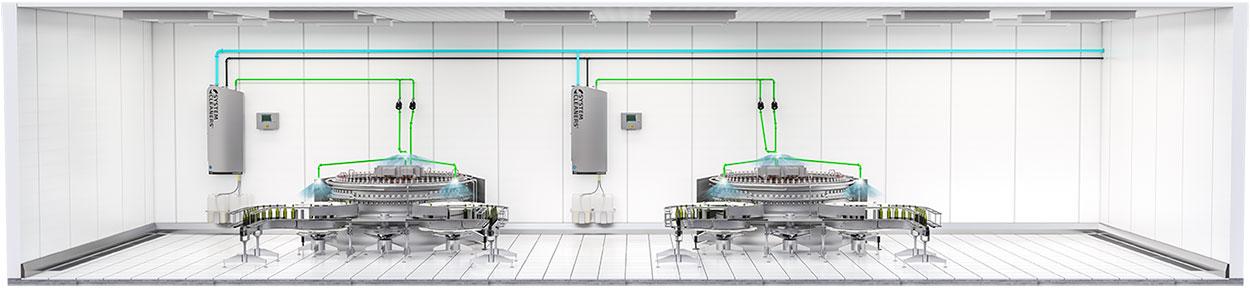

Decentral chemical supply

With a decentral solution, the concentrated chemicals are stored and dispensed at each workstation. This can be a main station or a satellite.

All cleaning units can rinse, apply foam and disinfect (depending on the choice of equipment), and the concentration of the chemicals can be adjusted for and at each workstation.

Decentral systems can be either fixed to the wall or mounted on a trolley (mobile units). Both wall mounted and trolley models can be used at the same processing site.

The system can be connected to mains water supply or to a boosted water supply from a System Cleaners supply station.

Advantages:

- Need for less modifications of piping system compared to a central system.

- No need for establishment of centralized chemical storage.

- Easy to install in existing facilities.

Hybrid chemical supply

A hybrid solution has the same setup as a central system but with the additional possibility of adding an extra product at all or some of the workstations.

Application

The solution is often applied when there is a need for an extra cleaning task to be performed independently of the regular cleaning program.

Low-pressure cleaning with boosted water offers a range of benefits

Significant reduction in cleaning time

Reduced water and chemical consumption

Less wear on processing equipment and affected surfaces

Improved work environment

Low maintenance and service requirements