SC click dosing valve

By turning a disk containing five different holes, the desired quantity of chemicals can be determined accurately.

Use the key, which is also used to lock the cabinet door, to adjust the chemical dosage.

Every time the setting is changed, a spring load will result in a click that will indicate that the valve is set in the desired position.

Note that the figures on the metering valve do not indicate the concentration.

Dosage is dependent on many factors such as product temperature, viscosity, density, pressure conditions, lenght of hose, air pressure etc.

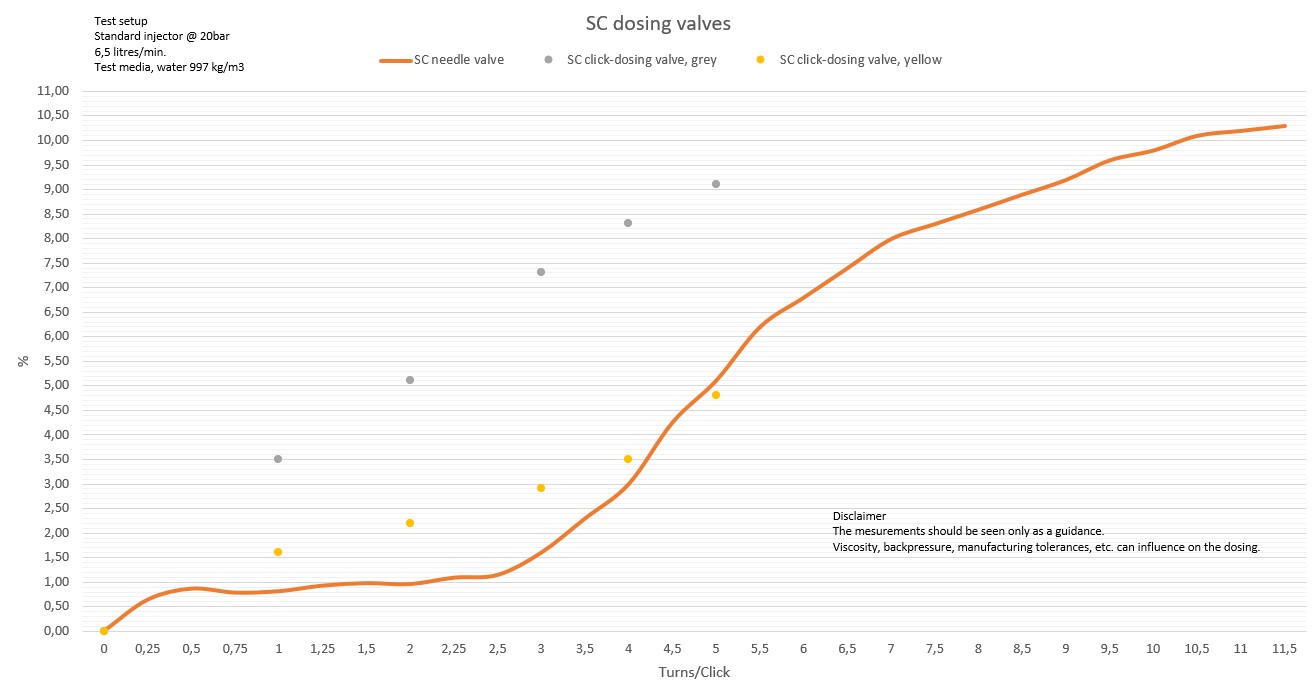

Consequently the mentioned percentages in below tables are only guiding.

We recommend that dosage is adjusted by your chemical supplier.

Dosing valve Grey - for foam products

| Air Pressure |

Position | ||||

| 1 | 2 | 3 | 4 | 5 | |

| Size of orifice | |||||

| 0,8 mm | 1,0 mm | 1,2 mm | 1,4 mm | 1,6 mm | |

| 0 Bar | 3,5% | 5,1% | 7,3% | 8,3% | 9,1% |

| 5 Bar | 3,5% | 4,8% | 6,3% | 7,3% | 8,1% |

| 6 Bar | 3,1% | - | 5,5% | - | 7,3% |

Dosing valve Yellow - for disinfection products

| Air Pressure |

Position | ||||

| 1 | 2 | 3 | 4 | 5 | |

| Size of orifice | |||||

| 0,5 mm | 0,6 mm | 0,7 mm | 0,8 mm | 0,9 mm | |

| 0 Bar | 1,6% | 2,2% | 2,9% | 3,5% | 4,8% |

| 5 Bar | 1,3% | 2,0% | 2,6% | - | 4,4% |

| 6 Bar | 1,3% | 1,9% | 2,3% | - | 4,4% |

Dosage is dependent on many factors such as product temperature, viscosity, density, pressure conditions, length of hose, air pressure etc.

Consequently the mentioned percentages in the illustration above are only guiding.